FactoryTalk Analytics DataFlowML

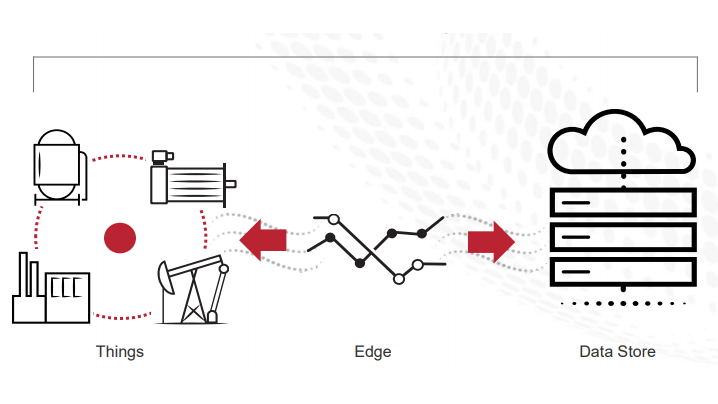

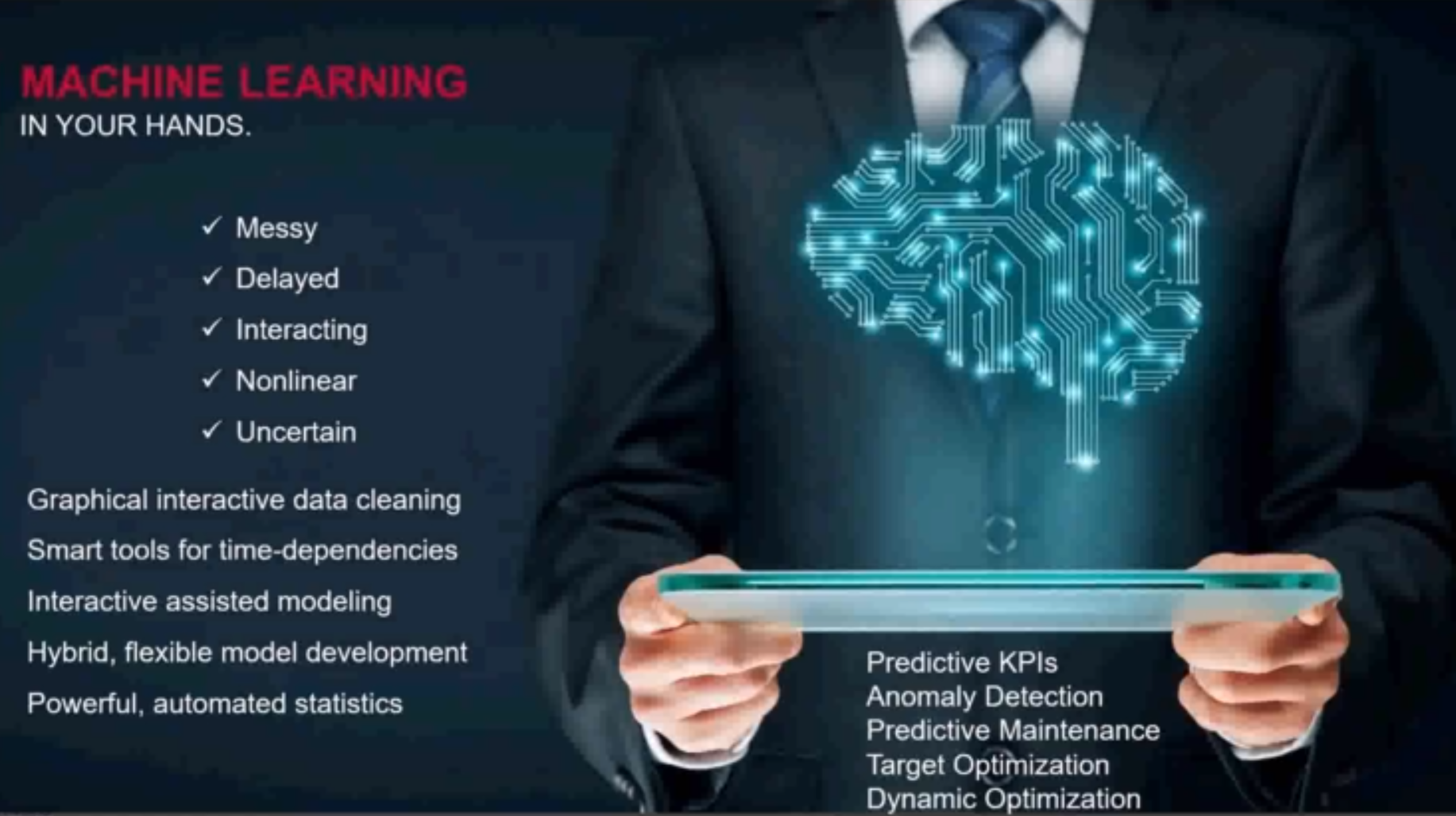

FactoryTalk Analytics DataFlowML is a big data analytics and ML platform that empowers data scientists to visually build, train, deploy, score, and monitor ML models. With the explosion of large-scale industrial batch and streaming data in manufacturing, data scientists are constantly expected to build intelligent applications and uncover enterprise-level insights across site and plants. To ensure a faster route to innovation at enterprise scale, they need to be enabled to build and deploy analytics solutions, including machine learning models on big data—and reuse at multiple locations. For this, data scientists need an open, standardized, secure, and enterprise-grade analytics platform on which they can collaboratively manage the entire model lifecycle in a centralized IT environment. While doing this, they should be able to blend and mashup data from multiple sources, leverage out-of-the-box open-source ML libraries for faster model building, and take advantage of pre-built ingress and egress data connectors to various IT or OT data sources.